The question arises from a simple idea. Do you feel like less of a woodworker if you follow a set of plans?

Or more accurately, do you feel like awkward when building a project that you didn't design? I used to, until I started developing plans for others to follow. That changed how I view plans. When I follow a plan, I immediately feel like a neophyte. And it's not because the project is necessarily complex, but rather I seem to slip into the mode of program versus user. I assume everything has been figured out for me, and all I need to do is the bidding of Master Control. We all need a Dumont to help us gain access to Master Control and break free of the bond that plans and cutlists can impose on us.

Here's what I do when I follow a plan. Before I cut wood, before I even order wood, I study the plan, nearly memorize the plan to the point that I know and understand every aspect of the project. Doing this, I make the plan my own project. It becomes my design, in effect. Nobody is holding my hand or a conductor's wand. I am in charge. I am the conductor. It's not a fun process though. It takes discipline. But so does developing your own idea. The beauty of following a plan is that you can be assured (if you trust the source) that many of the mistakes have already been worked out.

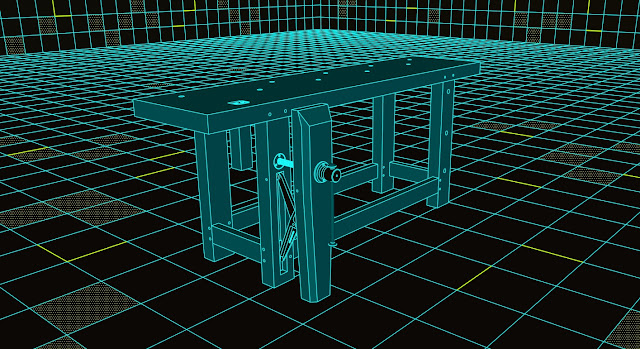

The plans we're developing for the Classic Workbench will reflect this philosophy. There will of course be schematics of the bench, like our Split Top Roubo, but there will also be succinct construction notes that will tell you the why of the design, not just the how. We want this design to become your's.

Some may question why we're releasing a bench design that doesn't include more of our products (like a wagon vise) and will cost about half of what it costs to build a Split Top Roubo. It's a valid question. And here's the answer. We're in this for the craft first. And we think if you're just getting into the craft, you should have the option to build a sweet bench with Benchcrafted functionality without emptying your wallet. This is that bench. If you've got the means, go all the way with our Glide and Tail Vise packages. But if you're just dipping your toes in, and you want to sample the wares without that little nagging in the back of your mind, the Classic is the bench to build.